How EAG Engineering Science Can Help CHIPS Act Projects Succeed

The CHIPS and Science Act is investing to grow the semiconductor industry in the United States. EAG can help.

Home » Understanding Flame Atomic Absorption Spectroscopy (FAAS)

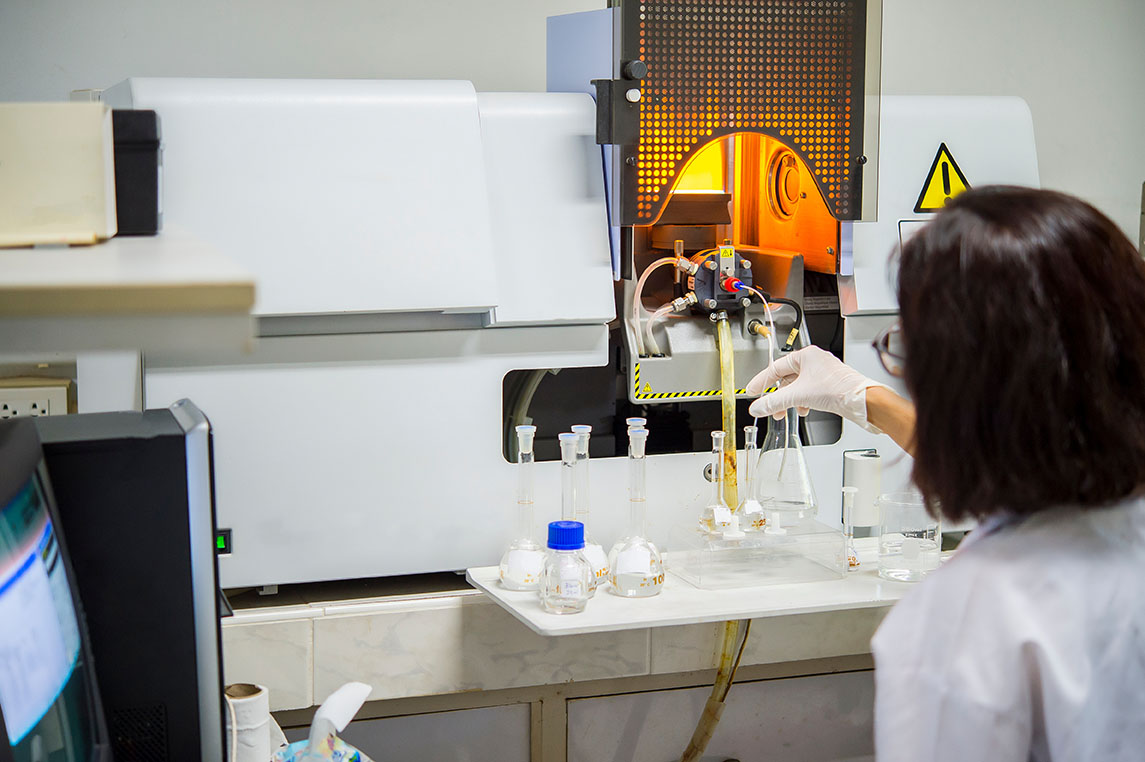

Flame Atomic Absorption Spectroscopy (FAAS) continues to play an important role in routine elemental analysis, even as laboratories have widely adopted Inductively Coupled Plasma-based instruments. While techniques such as ICP-OES and ICP-MS offer simultaneous multi-element analysis, enhanced sensitivity, and a wider dynamic measurement range than FAAS, they are not always the best choice for every application.

At Eurofins EAG Laboratories, FAAS is used when it best aligns with a client’s analytical goals, regulatory requirements, and sample matrix. In many cases, a robust, cost efficient, single-analyte-at-a-time technique like FAAS delivers accurate results faster and with far rarer spectral interferences than ICP techniques. Our technical experts are available to consult with you, review your analytical needs, and help determine the most appropriate technique to ensure reliable, actionable results.

FAAS measures elemental concentration by monitoring how much light is absorbed by free atoms in a flame. A sample is atomized using an air-acetylene or nitrous oxide flame, while an element-specific hollow cathode lamp emits light at a precise wavelength. The amount of absorbed light is directly related to concentration, allowing for reliable quantification using Beer’s Law.

Because FAAS targets one element at a time, it offers high selectivity and straightforward data interpretation.

FAAS is most effective for applications with concise analyte lists and moderate sensitivity requirements. It is often selected for routine, high-volume testing where speed, reliability, and regulatory alignment matter. FAAS is a good fit when:

FAAS offers several practical advantages that continue to make it a valuable technique in commercial analytical libraries:

FAAS is widely used for environmental testing of water and soils, quality control in foods, pharmaceutical, and personal care products, and industrial manufacturing, metallurgical and plating bath analysis, and digested geological or mining samples.

Despite advances in multi-element instrumentation, FAAS remains a practical and dependable tool in modern analytical laboratories. Its value lies in its efficiency, selectivity, and consistency when the application calls for targeted element measurement.

At Eurofins EAG Laboratories, we offer both FAAS and ICP-OES and select the technique that best fits each project’s technical and regulatory requirements. When the analyte list is focused and the goals are clearly defined, FAAS often provides the most efficient path to high-quality data. Consult an expert today.

The CHIPS and Science Act is investing to grow the semiconductor industry in the United States. EAG can help.

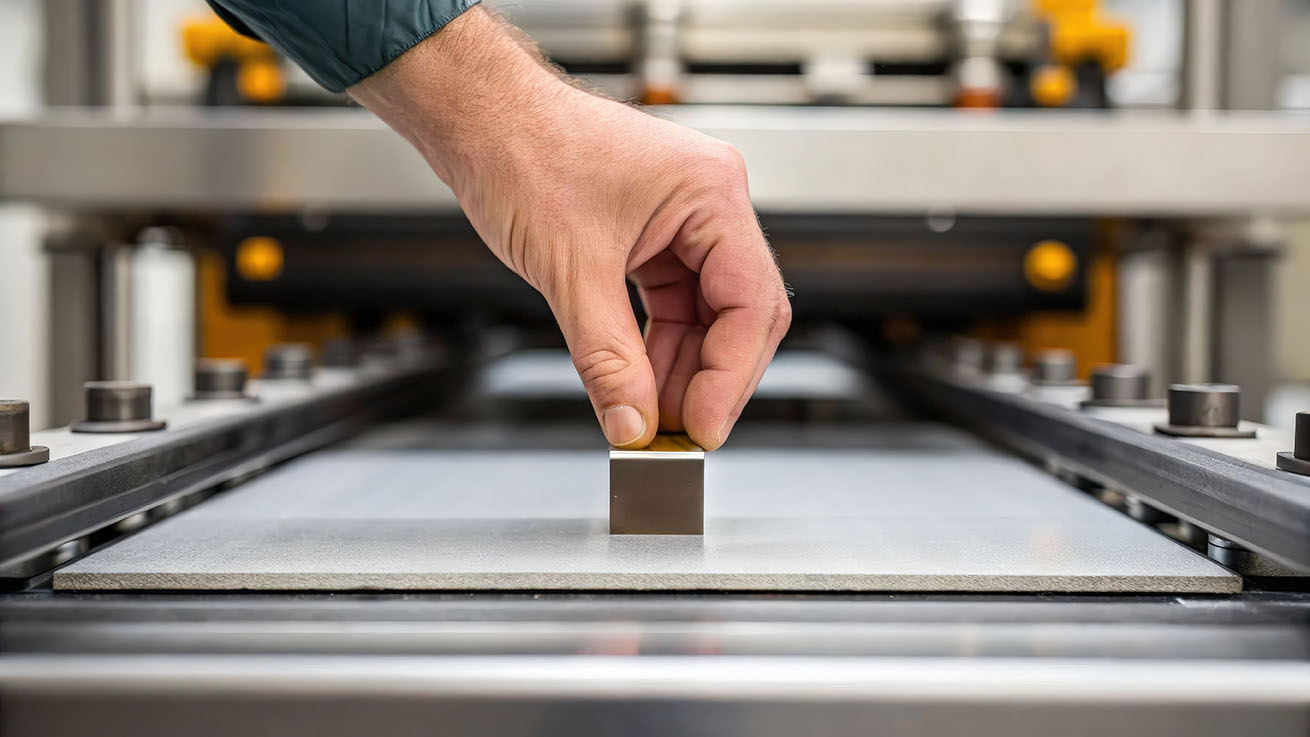

Rare earth magnets power some of today’s most advanced technologies. Part 3 of this series explores how the magnets are produced, challenges of maintaining purity at every step, and why precision analysis is essential for building a reliable supply chain.

Cryo TEM involves performing TEM analysis while keeping the sample at cryogenic temperatures, around -170°C.

XRD analysis provides identification of crystalline phases present. For 3D printed materials that come from a matrix of multiple elements, it can be unclear whether the cooling creates one, consistent phase of material or if it separates out into multiple phases.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.