Effects of Surface Roughness

The roughness of a surface and how it interacts with surrounding materials and elements can have a significant impact on material technology and its functionality.

Home » Effects of Stress on Medical Devices

Have you ever bent a paperclip back and forth until it broke into two pieces? It would be difficult to predetermine how many bends it would take to break it. It may only take a few bends but, depending on its structure, it could take a lot more, making it seem indestructible.

Imagine an implanted medical device, such as a pacemaker, which creates a repetitive movement several thousand times in a day. Wouldn’t you want the quality and reliability tested to verify longevity of the product? Residual stress measurements can help determine this.

Two common types of stress X-Ray Diffraction (XRD) can measure are tensile (pulling) and compressive (pushing) stress. When we think about a piece of metal bending, the outside of the bend would experience tensile stress because that part is getting pulled apart. The inside of the bend typically exhibits compressive stress because that part is getting squeezed together. Knowing the type of stress and how much there is in a small metal component in a medical device can be the determining factor on how well the device will perform, how long the device will last, or even whether or not the device is going to work at all.

Stress isn’t necessarily a bad thing. In fact, a pacemaker manufacturer might want their metal components to have higher residual stress to start. The pacemaker is going to make many repeated movements over the course of its use. Inherent stress in the metal can help prevent the material from breaking down and make it more resistant to cracking.

Residual stress measurements are very common analytical tests for all kinds of metal products. However, these measurements can be critical for medical devices such as pacemakers and stents.

Eurofins EAG has specialized tools and expertise for residual stress measurements. Our XRD tool is unique in that we can go down to a 20 micrometer spot size (The average width of a human hair is 100 micrometers)! Our small spot size capability is rare to find and is very beneficial when analyzing specific areas on a medical device. For example, we can analyze the inside of a hypodermic needle to verify crystallite orientation, also known as texture, which can affect how medication is administered through the needle.

Coupled with our very small spot size capability is the unique ability to collect data on our XRD tool with a 2D detector. With a 1D detector, you have limited area intensity. Our 2D detector provides way more crystallites in the diffracting condition, boosting the intensity of the data significantly. This means we can collect data on a very small spot, but it doesn’t take extensive amounts of extra time to collect the same counts you would collect with a standard spot size (1cm x 1cm).

At Eurofins EAG, our XRD scientists have years of experience with phase identification and quantification, stress measurements, texture analysis, and more. Contact us today to learn how we can help you with your next project.

The roughness of a surface and how it interacts with surrounding materials and elements can have a significant impact on material technology and its functionality.

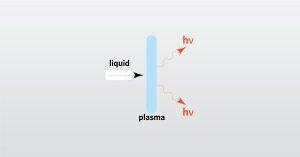

In this webinar we will focus on Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES), and ICP-MS

Analytical testing to support changes in raw materials and processing conditions used in manufacturing memory foam, as well as odor

Explore the hidden risks of impurities during manufacturing and how advanced methods like GDMS and ICP-MS help safeguard critical components.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.