Characterization of Plasma Altered Polymer Surfaces Webinar

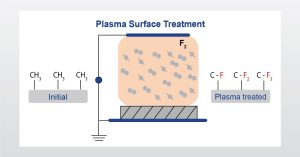

In the full webinar we will discuss how the surface properties of polymers are altered by plasma treatment using characterization techniques

Home » Food Packaging Materials Testing

Food packaging materials can be made with plastics, paper and board, glass, metal, wax, and printing inks. These packaging materials are directly and indirectly in contact with our food.

Eurofins EAG Laboratories offers a wide range of analytical instruments and capabilities to support the food industry with packaging testing including research and development, regulatory compliance, product safety, migration and failure analysis. From standardized methods for food contact testing to customized methods for specialty materials, EAG can help.

Example approaches for food safety and contamination testing:

Food packaging was exposed to a warehouse fire. There was concern about smoke residue on the packaging material. A comparative analysis was conducted on the inside of exposed versus unexposed packaging.

Extracts of the packaging were analyzed using GC-MS compared to a polyaromatic hydrocarbon (PAH) mixed analytical reference standard (indicative of smoke residue). The results indicated smoke damage for certain cargoes located close to the fire, while products further away from the fire showed no sign of smoke damage.

Example approaches for packaging failure analysis:

A metal can containing an epoxy liner was used for food packaging. However, the epoxy liner was delaminating from the inside surface of the can. A comparative analysis was conducted on a control versus suspect can looking for incorrect epoxy application (using cross sectional analysis and microscopy for film thickness), insufficient epoxy curing (using modulated DSC), and contamination (using GC-MS, FTIR, and EDS). We successfully identified the failure was caused by oil contamination.

Techniques that can be used for materials characterization and deformulation:

A specialty casing material was deformulated to determine the initial raw material and additive package. The starting materials, dyes, flavor package, thickness and strength of the casing were reported, and the client was able to make this specialty casing based on information provided.

Contact our team for help with your device testing needs.

In the full webinar we will discuss how the surface properties of polymers are altered by plasma treatment using characterization techniques

Eurofins EAG Laboratories stands ready to assist in the analysis of lithium-ion batteries from the raw material supply chain through to the finished product and eventual recycling.

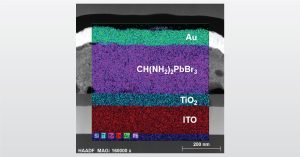

In the full webinar we will discuss Thin Film Analysis that looks at film composition, thickness, and uniformity.

RBS is the one technique where we can really say that the composition and concentration are accurately determined for thin films.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.