Ask the Expert: Composition and Contaminant Measurements of Solid State Materials

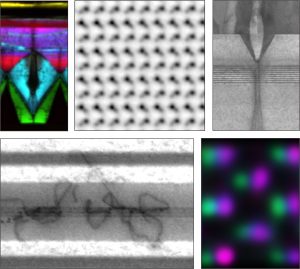

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding materials analysis with various X-ray and ion beam analytical techniques.