For Medical Device Testing, Every Variable is Important

The analytical evaluation threshold (AET), an important part of the extractables and leachables testing in these studies, needs to be calculated for each instrumental technique.

Home » Polymer Case Study: Blistering Paint

What causes blistering or bubbling within a coating or paint film? These unsightly spots can stem from several factors including moisture entrapment or permeation, contamination, excessive application of coating and more. Blistering paint indicates that the coating is failing, and investigation is needed.

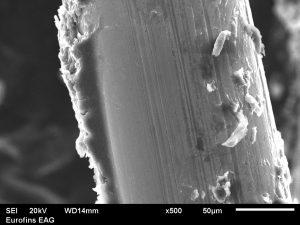

Blisters were observed in paint applied to steel plates that had undergone treatment with a corrosion inhibitor. An investigation was performed to determine if there was evidence of contamination on the inside of the blister.

Paint from a smooth area was removed with a scalpel to serve as a control. A comparison of the elemental profile of the underside of the blister was made with the control paint section. Elements commonly associated with salts (potassium, sodium, and chlorine) were detected by SEM-EDS only on the blistered samples. The blistered area also exhibited a brown color, whereas the control counterpart was green.

The brown coloration and the presence of salts were indicative of corrosion, suggesting the steel surface had not been properly cleaned prior to paint application.

For more than 50 years, scientists and engineers at Eurofins EAG have investigated and resolved product failures for clients. Our team of experts identify key failure indicators and follow them to the root cause.

Failure analysis of plastics, thermosets, and rubber materials is commonly performed on finished products and typically involve comparative analysis between failed and non-failed samples. Once the potential root cause is identified, experiments can be designed and conducted to test the hypothesis and recreate the failure in the laboratory. Eurofins EAG can evaluate a variety of polymer types, including:

Eurofins EAG Laboratories offers a full suite of analytical techniques to evaluate the identity, composition, morphology, topography, and rheology of polymeric materials and components.

Call +1 800-366-3867 or email us.

The analytical evaluation threshold (AET), an important part of the extractables and leachables testing in these studies, needs to be calculated for each instrumental technique.

Women in STEM Career Fair Eurofins EAG Laboratories is excited to host a Women in STEM Career Fair on March 31st from 3 PM – 6 PM ET! We’re looking

This webinar covers FDA regulation of medical devices, the most commonly used test standards, and custom testing at Eurofins EAG Laboratories.

VCSELs have several advantages, such as a higher modulation speed, which make them great for technological innovations.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.