Principles and Strengths of In Vitro Testing

In Vitro testing uses cell-based biological models instead of animals or humans.

Home » Molded In Stresses

Used to create custom plastic designs, thermoforming is a manufacturing process that includes heat, vacuum, and pressure to form plastic sheets into three-dimensional molded shapes. Thermoformed packaging is created for the food, pharmaceutical and electronics industries.

Cracks were observed in transparent thermoformed plastic packaging during routine visual quality checks. The failures were occurring in specific material lots that may have corresponded with a reported equipment change.

A comparison was made between known good and known bad lots to investigate the root cause. Based on DSC, the bad lot exhibited an endothermic peak near the glass transition in the initial heating cycle that was absent in the good lot. This peak is an enthalpic recovery peak associated with molecular relaxation. Samples were examined under a strain optical polarimeter at a specific location on the thermoformed parts.

The images revealed significant differences in the birefringence patterns, suggesting a higher level of residual stress in the bad lot. High residual stresses imparted during the thermoforming process were likely responsible for the cracking issue.

For more than 50 years, scientists and engineers at Eurofins EAG have investigated and resolved product failures for clients. Our team of experts identify key failure indicators and follow them to the root cause.

Failure analysis of plastics, thermosets, and rubber materials is commonly performed on finished products and typically involve comparative analysis between failed and non-failed samples. Once the potential root cause is identified, experiments can be designed and conducted to test the hypothesis and recreate the failure in the laboratory. Eurofins EAG can evaluate a variety of polymer types, including:

Eurofins EAG Laboratories offers a full suite of analytical techniques to evaluate the identity, composition, morphology, topography, and rheology of polymeric materials and components.

Call +1 800-366-3867 or email us.

In Vitro testing uses cell-based biological models instead of animals or humans.

Join us for an engaging in-person event at our Sunnyvale CA lab.

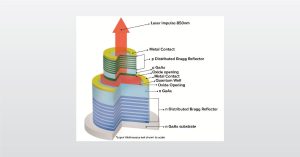

In the full webinar we will introduce analyzing VCSELs with a focus on secondary ion mass spectrometry (SIMS)

Low-E Coatings on glass are a high efficiency protection of a glass surface for transparency. These coatings help the glass become energy efficient to allow the sunlight to come in or reflect out.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.