Glass Analysis

Home » Services » Materials Testing & Analysis » Glass Analysis

Glass is a crucial element in numerous applications. We have unmatched expertise in detailed glass analysis to assess quality.

Today there is more glass in use than ever before. It is a critical design component encompassing environmental protection, appearance, safety, light transmission, and thermal management. The increasing importance and sophistication of glass means that more advanced analyses are needed to address manufacturing issues.

Serving the entire glass value chain

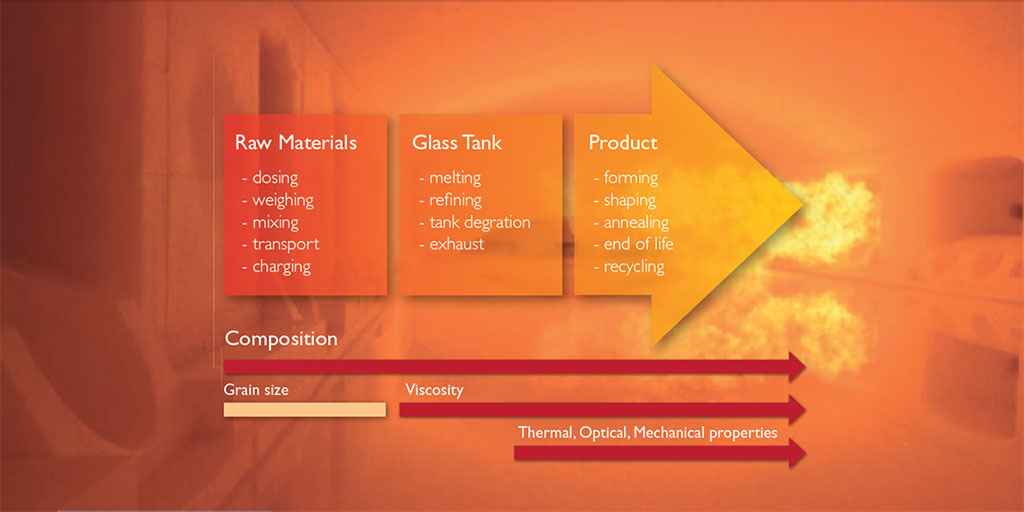

For over 40 years, EAG has been involved in the entire value chain, from raw starting material to final products. We investigate the composition and quality of raw materials and production glass, give research and development support to glass factories during process optimization, glass tank wear-out studies, verification tests and failure analysis investigations. Furthermore, in the field of surface modification, delamination, and corrosion of coatings, EAG has unmatched expertise.

Glass analysis applications

- Compositional analysis of glass and glass products

- Bulk composition

- Recycle glass characterization

- Surface composition

- Surface modification

- Coating on glass

- Coating identification

- Effects of glass tempering

- Transparent conductive oxide (TCO) analysis

- Physical properties

- Viscosity

- Thermal expansion behavior and stress

- Electrical resistance

- Optical properties

- Defect analysis

- Classification of defects: a systematic approach

- Inspection techniques for glass defects

- Chemical analysis of glass defects

- Analysis of refractory materials

- Corrosion/delamination/degradation for pharmaceuticals

Related Resources

- Webinar: Glass Analysis

- Webinar: Analyses of Modified Glass Surfaces

- App Note: Analytical Techniques for Glass

- App Note: Glass Delamination in Pharmaceutical Vials

- App Note: Contact Lenses: Understanding Surface Chemistry

- App Note: Identifying Contaminants Using Raman

- Industry: Medical Devices

- Industry: Consumer Electronics

- Industry: Pharmaceuticals

- Industry: Semiconductors

Would you like to learn more about Glass Analysis ?

Contact us today for your Glass Analysis needs. Please complete the form below to have an EAG expert contact you.