A Deep Dive into High Powered Electronics

High Powered Electronics are used in a wide suite of applications, from consumer electronics and electric vehicles to railways and power plants and even artificial intelligence.

Home » Consumer Electronics

High Powered Electronics are used in a wide suite of applications, from consumer electronics and electric vehicles to railways and power plants and even artificial intelligence.

In vitro biocompatibility testing is a powerful tool in the risk assessment of wearable devices. View our webinar to learn more!

February 12, 2025

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding Silicon Carbide for High Powered Electronics. EAG Laboratories has a vast depth of experience analyzing silicon carbide using both bulk and spatially resolved analytic techniques and is the world-leading materials characterization and engineering resource for semiconductor testing.

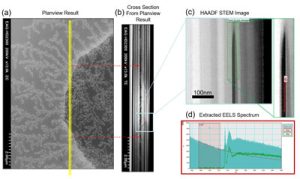

There are many key components of the VCSEL, but one challenging region is the oxide aperture. The oxide aperture is responsible for current confinement, and it is important to have high quality oxidation to prevent failure of the device.

EAG provides essential services for common devices and platforms that are instrumental to the electronics industry. These include artificial intelligence, ASICs, PCB Assembly, and Discretes.

In the early stages of materials development for consumer electronics, a myriad of technologies comes into play, including semiconductors, MEMs & NAND structures, plastics, glass, and various raw materials.

As a trusted partner in the consumer electronics industry, we are ready to meet the evolving industry needs, advancing innovation and excellence.

One of our surface analysis techniques, TOF-SIMS, can be used to characterize the surface coatings on screens and to compare the thickness of the coatings using depth profiles.

The term ‘rare earth elements’ (REEs) is a misnomer and better refers to the relatively rare ores REEs are extracted from; rare earth elements are all around us!

As the list of restricted substances grows, testing demands customized methods to identify issues early. This is a complex issue that requires a strategic approach.

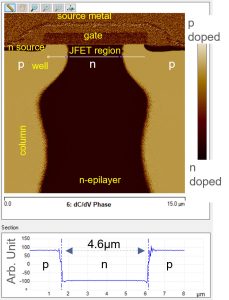

SCM provides doped region distribution mapping, profiling and dimensional analysis for the research and development, failure analysis and quality control of electronic components.

Improper aperture oxidation can lead to high stress or introduce unintended defects ultimately resulting in failure. Here, we present a study using STEM EELS to provide a method for measuring differences in oxygen bonding.

Vertical-cavity surface-emitting lasers, or VCSELs, play a major role in the consumer electronics 3D sensing industry.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.